Visit Our Sponsors |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Aggressive driving, cellphone use and physical hazards in the warehouse are all common roots of forklift accidents, which can be dangerous for employees and costly to logistics organizations. Holman Logistics was experiencing hundreds of these incidents each year, and the third-party logistics provider was looking for a solution to improve and maintain safety.

Holman provides warehousing, manufacturing support, multi-modal transportation and omnichannel fulfillment services for U.S. multi-client and dedicated locations ranging from 250,000 square feet to more than 1 million square feet. Its clients include Fortune 1000 companies in consumer goods, food and beverage, electronics, home appliances, heavy equipment, raw materials and more.

The company had already enlisted technology, training and other resources to maintain superior safety performance, but management was eager to better understand the root causes of forklift accidents at its facilities — and determine whether a new solution could help prevent future incidents. Holman’s senior executives were intrigued by the benefits that artificial intelligence tools were producing in the logistics industry, and they initiated a pilot partnership with AI solutions provider OneTrack.

Based in Chicago and Austria, OneTrack aims to help warehouses run safely and efficiently using computer vision and deep learning technology. Here’s how it works: A lift-mounted 360-degree camera captures images from the forklift on a 24/7 basis, while onboard algorithms and software parse out advanced data from those images in order to make sense of what is occurring in the warehouse. The cameras connect to OneTrack’s system in the cloud, which offers real-time monitoring. The solution is able to determine and recognize patterns — and more importantly, anomalies from those patterns — within the captured data, and eventually, it can predict when those trends and anomalies will occur.

Holman and OneTrack began working together in early 2019 at two warehouses in Washington. For the pilot program, OneTrack was looking to demonstrate the ability of its machine-learning software to deliver a measurable improvement in forklift safety and productivity that would outperform the existing, non-AI legacy system that Holman had been using to track safety infractions.

OneTrack’s pilot provided targeted data on forklift impacts with equipment, pedestrians and other vehicles. Camera footage and real-time updates allowed warehouse managers to instantly review the incident and provide driver coaching in order to improve operator behavior. Holman began to see significant reductions in safety incidents, and decided to move forward with the solution at more locations.

Accident-Free Operations

In Maumelle, Arkansas, Holman’s 440,000 square-foot warehousing and manufacturing plant for consumer goods multinational Kimberly-Clark was challenged with inefficient “signal-to-noise” incident ratios — and receiving too many alerts on non-actionable items. The facility’s legacy system was unable to differentiate between typical activities that occur in the domain of warehouse activity — such as forklift operators driving over bumps, cracks, debris and dock plates — vs. actual safety incidents.

As a result, warehouse managers were receiving far too many false-positive alerts from the system, and they were wasting time on inaccurate information. After implementing OneTrack, they were able to see precisely classified incident reports with higher levels of data-specificity, allowing for more targeted feedback.

Videos generated by on-board cameras also offer definitive proof of the circumstances of each safety incident, making it easy to perform root-cause analyses, according to managers at the Kimberly-Clark site. The videos have proven “indispensable” as tools for proactive driver coaching and are used during training when onboarding new operators at the facility.

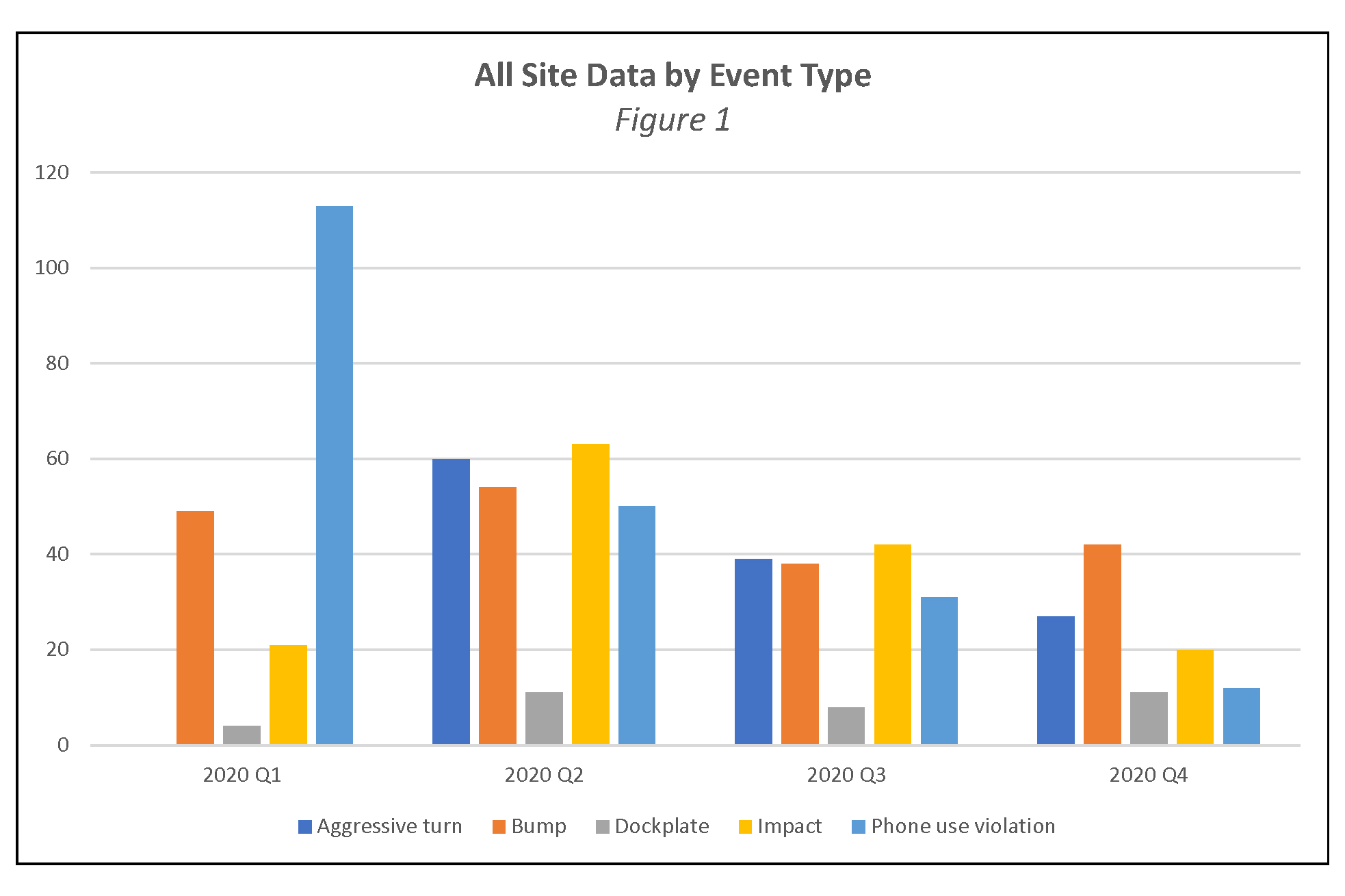

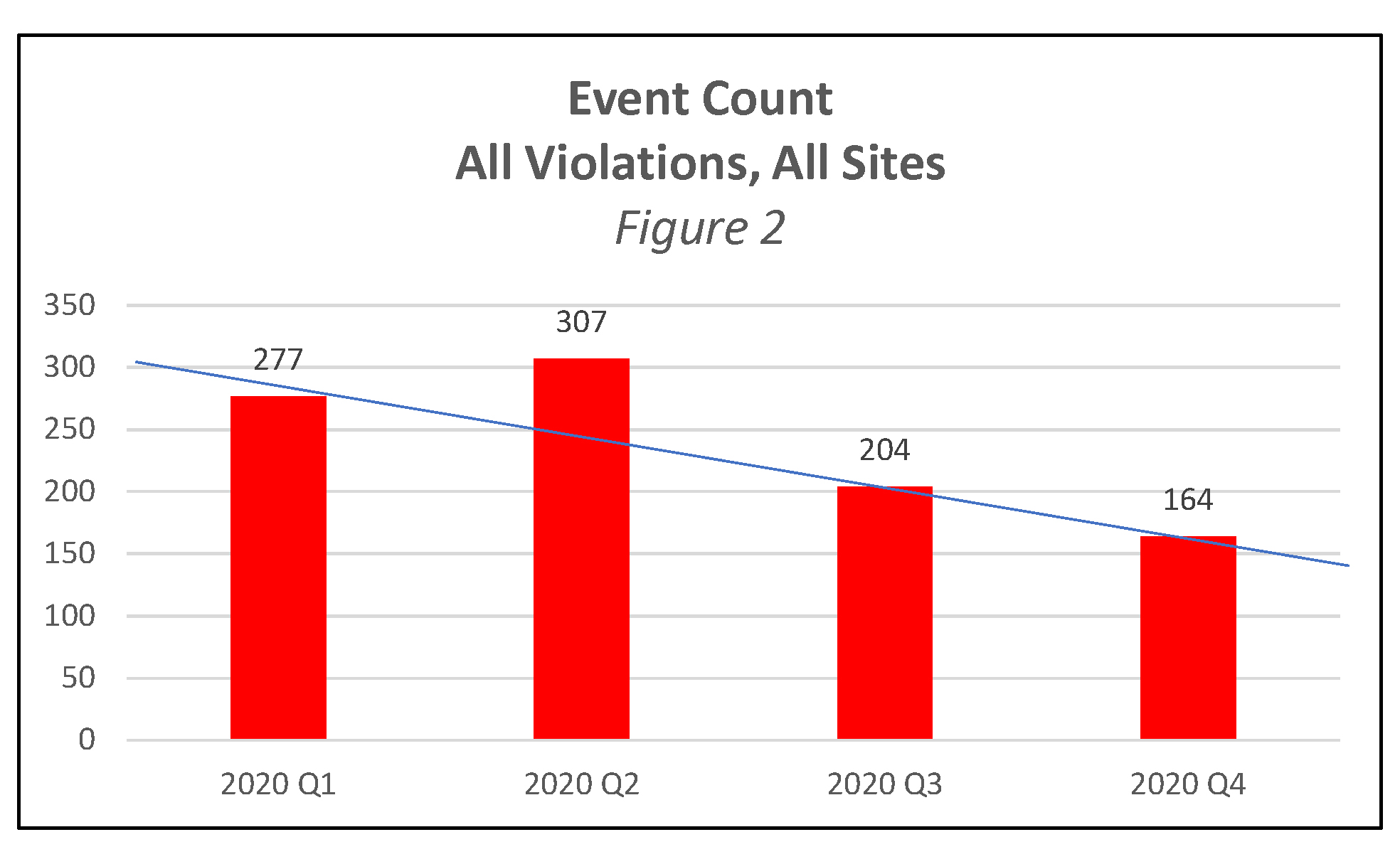

Combining the AI tools with an advanced focus on safety has allowed the facility to move closer to a goal of accident-free operations. Phone-use violations, aggressive turns and forklift impacts dropped throughout 2020. Overall driver violations were nearly halved from the second to fourth quarter. Over time, further improvements can be expected as the AI continues to learn and more accurately predict potential incidents.

“Instead of being reactive when impacts occur, we can be proactive,” said one warehouse manager. “We are alerted right as mistakes are happening — or even before they occur — so we can coach the drivers and make them better drivers before the next impact occurs.”

RELATED CONTENT

RELATED VIDEOS

Timely, incisive articles delivered directly to your inbox.